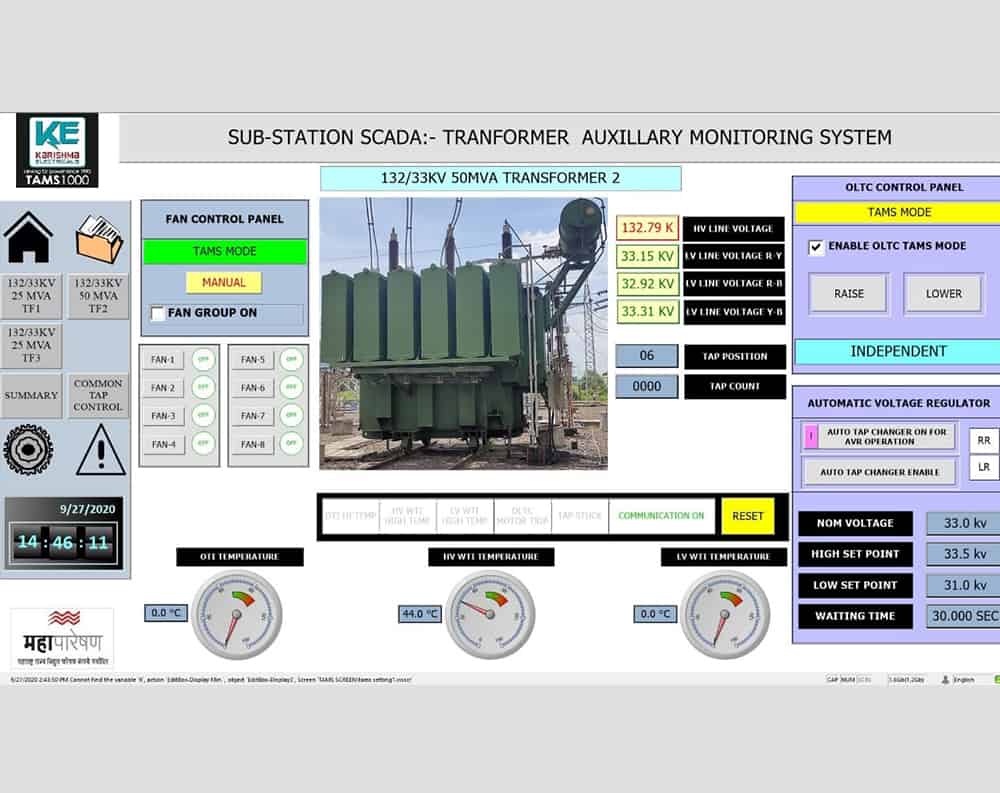

Transformer Auxiliary Monitoring System

![]() Overview

Overview

Transformer is key component of the power system. To be competitive in business, stakeholders are under pressure to maximize transformer availability, reliability, and performance. Usually, transformers are mostly managed and maintained in traditional way which have limitations. Above can only be achieved by use of smart technology which is presented in our TAMS

![]() What is this ?

What is this ?

Our UGTMS 1000 is state-of-the-art centralized system for monitoring and diagnostic system for transformer operation & maintenance and on-site diagnostics

Being Smart Equipment, it use analytics to provides the health of the transformers main component providing intelligent alarms & optimize operation & maintenance.